How to build a commercial greenhouse: From choosing the right structure (high tunnel, ground-to-ground, gutter-connected, or glass) to design, permitting, purchasing, installation, and warranty.

Helps growers make informed decisions by outlining key considerations like site selection, foundation types, manufacturer selection, and construction options (self-build, supervised, or turnkey).

Highlights Harnois Greenhouse’s full-service support, offering engineered structures, local expertise, flexible installation, and ongoing after-sales service tailored to commercial growers in Canada and the northern U.S.

Whether you’re expanding an existing farm or launching a new horticultural business, building a commercial greenhouse is a strategic investment that enhances productivity, extends the growing season, and provides better control over crop quality. However, designing and building a structure tailored to your needs requires careful planning. These steps to Build a commercial greenhouse will walk you through each phase—from understanding greenhouse types to managing permits, purchasing, construction, and warranties—so you can grow with confidence.

Types of Greenhouses

Greenhouses come in different configurations to suit your operational needs and space constraints. This section of the Greenhouse Building Guide explains the different types of greenhouses but also the different types of greenhouse structures.

Attached Greenhouses

Built against an existing structure, attached greenhouses save space and benefit from shared utilities. However, their size and orientation are restricted by the adjoining building.

Best suited for: Headhouses, propagation, or supplemental growing areas.

Detached Greenhouses

These standalone units offer complete design freedom, better light distribution, and airflow control. They also reduce the risk of pest and disease transfer between crops.

Best suited for: Independent growing operations and crop isolation

Gutter-Connected

Multiple greenhouses are joined at the gutters to form a large, contiguous growing area. These are ideal for automation, zoning, and efficient land use.

Best suited for: High-output commercial operations with climate zoning needs.

Build a commercial greenhouse : Types of Greenhouse Structures

Choosing the proper structural design is a core part of any Greenhouse Building Guide. The structure type affects durability, ventilation, crop flexibility, and investment costs.

High Tunnel Greenhouses

These unheated greenhouse structures extend the growing season and provide protection from rain, wind, and frost. Their low cost and quick installation make them ideal for small fruit and vegetable growers.

Advantages:

- Economical

- Easy to move or modify

- Excellent ROI for field crops

Freestanding Greenhouses

A popular option for scalability and customization, freestanding structures can be used individually or grouped for different crops or climates.

Advantages:

- Full light exposure on all sides

- Easily expandable

- Simple layout for crop rotation

Gutter-Connected Greenhouses

Designed for high-tech operations, these systems enable multiple bays to share climate control, irrigation, and automation equipment. Gutter-connected greenhouses maximize usable space and support high crop turnover.

Advantages:

- Scalable and modular

- Suited for automation

- Efficient for heating and cooling

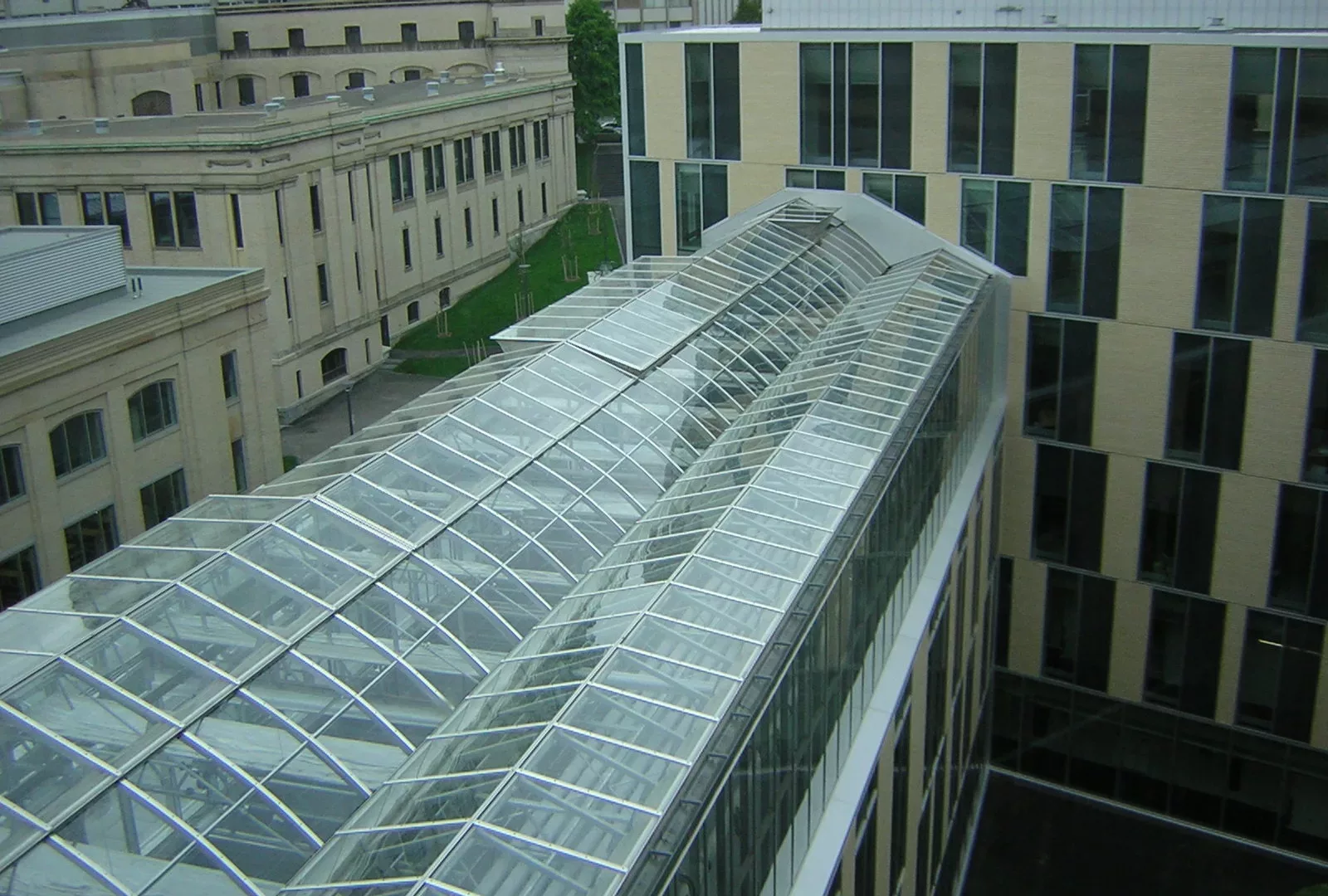

Glass Greenhouses

Preferred for agro-industrial and research projects, glass greenhouses offer unmatched light transmission and a long lifespan. Though they cost more upfront, they deliver high performance for specific markets.

Advantages:

- Aesthetically pleasing

- Long-lasting with proper maintenance

- High light levels

Note: Polyethylene-covered greenhouses are still more common for growing vegetables and soft fruits due to their cost, flexibility, and ease of repair.

Estimated Costs for Different Greenhouse Structures

As part of this Greenhouse Building Guide, it’s important to understand how structure type affects projected costs. According to Harnois Greenhouse, commercial greenhouse pricing ranges from roughly $6 to $60 per square foot, depending on size, materials, and level of automation harnoisgreenhouse.com+10harnoisgreenhouse.com+10harnoisgreenhouse.com+10. Here’s a rough breakdown:

-

High tunnels are the most affordable option—typically around $2–4/ft², ideal for seasonal field crops or trial installations.

-

Freestanding greenhouses fall in the mid-range: approximately $15–20/ft², offering greater structural flexibility and durability.

-

Gutter‑connected structures, designed for large‑scale production and climate control, typically run between $20–50/ft² when fully equipped.

-

Glass greenhouses are at the high end—commercial glass projects can easily approach or exceed $60/ft² once structural work, systems, and glazing are included.

To explore detailed pricing and examples for your project, visit Harnois’s commercial greenhouse cost guide here: Commercial Greenhouse Cost.

Build a commercial greenhouse: Steps

Your greenhouse design should align with production goals, crop requirements, and site conditions.

1. Permits and Regulations

The first step in this Greenhouse Building Guide is checking local codes. Most commercial greenhouses require permits that comply with snow, wind, seismic, and fire codes.

Tip: Choose a manufacturer who provides site-specific stamped plans to streamline the permit process.

2. Greenhouse Plans and Layout

Decide on your footprint, height, bay width, and row layout. Include:

- Roof type (gothic or curved)

- Arch spacing

- Sidewall height

- Door placement

- Irrigation and ventilation layout

Key takeaway on how to build a commercial greenhouse: Plan with scalability in mind—modular designs reduce long-term costs.

Why Growers Choose Harnois: A Van Belle Case Example

When it comes to selecting a greenhouse supplier, commercial growers often look beyond just the price tag. Reliability, clarity, and long-term value play a critical role in the decision-making process. At Van Belle Nursery, project manager Alfredo Contreras led an extensive evaluation of suppliers to ensure the chosen partner could meet the operation’s technical and logistical needs. His experience highlights what sets Harnois apart when it matters most.

3. Site Location

Select a flat or gently sloped site with southern exposure, good drainage, and proximity to water and electricity sources.

Key elements to factor in to build a commercial greenhouse:

- Avoid tree shade or tall buildings

- Ensure vehicle access for deliveries

- Allow buffer zones for snow removal

4. Measure and Stake Out

Use a site plan and marking tools to verify dimensions, check for slope, and align the structure with the sun and prevailing winds. Soil tests are recommended for determining anchoring and drainage requirements.

5. Foundation Types

Your greenhouse foundation will depend on the type of greenhouse, climate, and local building codes.

- Concrete footings: Required for heavy snow or permanent installations

- Helical anchors or ground screws: Used in high tunnels and relocatable greenhouses

- Stem walls: Provide additional crop height and thermal mass

Greenhouse Building Guide: Purchasing Steps

Choosing a Greenhouse Manufacturer

This section of the Greenhouse Building Guide help you in selecting a reliable manufacturer is essential to your greenhouse’s long-term success.

What to look for:

- Proven experience in commercial agriculture

- Custom engineering adapted to your region

- Quality materials (galvanized or powder-coated steel, certified poly covers)

- Technical support in your language (e.g., English and French)

- Transparent warranty and service options

Bonus Tip: Working with a North American manufacturer, like Harnois, ensures compatibility with local codes and faster lead times compared to overseas options.

Greenhouse Building Guide: Installation Steps

This section of the Greenhouse Building Guide helps you select the most suitable construction method for your operation and budget.

Self-Installation (Auto-construction)

Some growers opt to assemble their greenhouse with a small crew and detailed manuals.

Pros:

- Reduces labor costs

- Complete control over the schedule

Cons:

- Higher risk of mistakes

- Longer installation time

Supervised Installation

You hire a local crew, but the greenhouse supplier provides an experienced supervisor for oversight and training.

Pros:

- Faster and more accurate

- Ideal for mid-sized projects

Cons:

- Requires coordination between your crew and the supervisor

Turnkey Installation

Your manufacturer or a certified contractor completes the full installation, from site prep to handover.

Pros:

- Single point of accountability

- Professional results and warranty coverage

Cons:

- Higher cost, but fewer surprises

Service After Installation

Look for companies offering:

- Fast replacement parts

- On-site service or remote support

- Scheduled re-covering or maintenance options

How Harnois Greenhouse Can Help Growers at Every Step

At Harnois Greenhouse, we support commercial growers through every phase of their greenhouse project: From design to installation and beyond. With over 60 years of experience, our team offers personalized guidance to help you select the ideal structure for your climate, crops, and objectives. Whether you’re building a freestanding greenhoue or a fully automated gutter-connected greenhouse, we can supply stamped engineering plans, foundation recommendations, and layout advice to streamline your permitting process.

Our commercial greenhouses are designed for North American conditions, with durable steel frames, high-quality coverings, and scalable configurations. You can choose between self-build, supervised, or turnkey installation, and we back every project with strong warranties and responsive after-sales support.

Qualified In-House Talent

With bilingual service and local expertise, Harnois is committed to helping you grow efficiently, sustainably, and with confidence, every step of the way.

Greenhouse Building Guide for Commercial Growers: Get started with Harnois

A commercial greenhouse is more than a structure—it’s a production tool that must meet your farm’s evolving needs. By following this Greenhouse Building Guide, you’ll make informed decisions every step of the way: from selecting the right structure type to navigating permits, choosing a trusted supplier, and deciding how to build.

Whether you’re investing in high tunnels for berry production or a high-tech gutter-connected facility, the key to long-term success lies in thoughtful design, quality materials, and expert support. Plan well, and build for growth with our Greenhouse Building Guide.

Contact us today to get started with a custom quote and discover how a Harnois high tunnel can transform your growing operation.