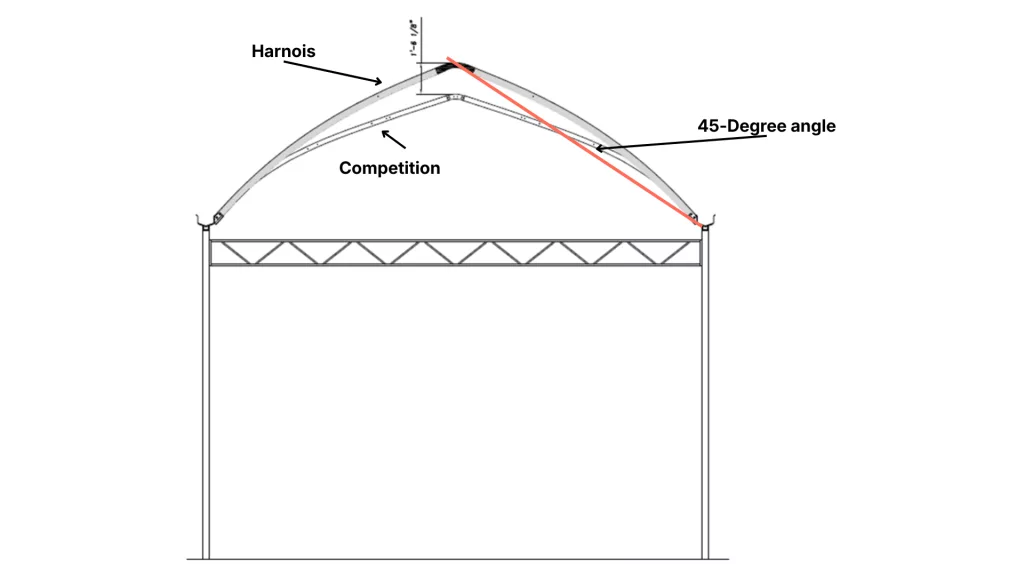

When designing a professional greenhouse, every structural choice affects performance, longevity, and crop results. Among these choices, none impacts overall efficiency more than the shape of the steel arches.

Traditional greenhouse frames use round or square steel tubes. While functional, these profiles limit structural performance, restrict luminosity, and add long-term operational costs.

Today, the oval tube greenhouse represents the most advanced step forward in greenhouse engineering. Thanks to its optimized geometry, the oval tube delivers exceptional strength, increased light transmission, longer poly-film life, faster installation, and unique design advantages such as safe drilling in the neutral axis; a feature not possible with round or square tubing.

This article explains why the oval tube greenhouse has become the preferred choice for commercial growers across Canada, the northern U.S., and demanding climates worldwide.

Oval Tube Greenhouses: Superior Strength, Maximum Luminosity, and Smarter Engineering

What Makes the Oval Tube Different?

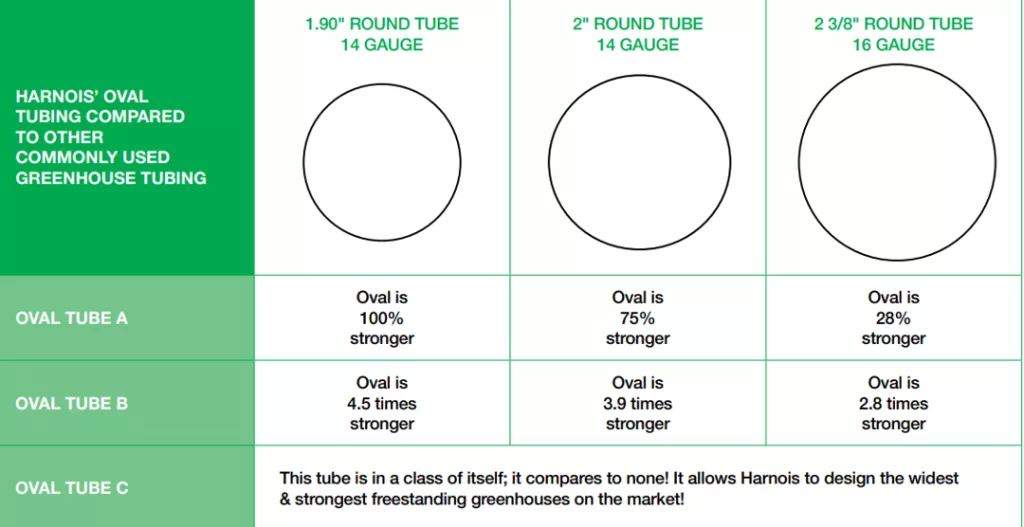

- 28% stronger than round tubing

- 46% stronger than square tubing

- 18% stronger than rectangular tubing

Superior Structural Resistance Under Snow and Wind Loads

Greenhouses in northern climates must withstand extreme loads. Snow accumulation, rapid freeze–thaw cycles, and strong winds can quickly reveal weaknesses in traditional round or square tubing.

The oval tube excels under these conditions because of its:

- higher bending stiffness

- lower deformation under load

- aerodynamic profile that reduces wind suction

- wider stress-distribution area

These qualities allow growers to build stronger greenhouses without increasing steel weight; a major advantage when aiming for optimal cost-performance balance.

A structure that holds its shape under pressure also keeps its poly cover tighter and more resistant to flapping, abrasion, and tearing. The result: fewer repairs and a significantly longer structural lifespan.

Better Light Transmission = More Yield

Light is one of the most valuable resources in a greenhouse. Any shading from the structure directly reduces crop productivity.

Because the oval tube is naturally stronger, arches can be spaced farther apart than in round- or square-tube designs, without sacrificing strength or safety. This reduces the number of shadows cast onto the growing area.

More light reaching the crop canopy increases yield potential, especially in winter.

1% more light ≈ 1% more yield

Corenthin Chassouant, M.Sc., Agronomist & Greenhouse Expert

mooth Profile = Longer Poly Film Life

- a smooth, edge-free surface

- Reduced friction during installation

- minimal film movement wear

- improved tension uniformity

Faster Installation and Better Material Efficiency

Oval tubes make greenhouse installation faster and easier thanks to:

- fewer arches

- Reduced steel usage

- wider spans between posts

- simplified assembly with bolted joints

- less on-site drilling

Because the arches are more spread out, the greenhouse requires fewer structural elements, which reduces:

- material cost

- installation time

- labour cost

- freight volume

This is why oval tube greenhouses are preferred by professional installers and high-volume growers looking to optimize ROI.

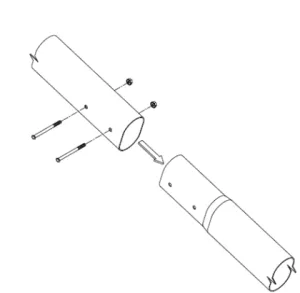

Drilling in the Neutral Axis

- The neutral axis is wider and more accessible.

- Stress distribution is optimal due to the oval geometry.

- Drilling can be performed without compromising the bending resistance.

- Their neutral axis is too narrow.

- Drilling risks penetrating high-stress areas

- It can weaken the arch and reduce load capacity.

Why this matters for commercial greenhouses

- swedged (crimped) tubes that fit precisely

- bolted assemblies instead of self-drilling screws

- longer-lasting, more secure connections

- factory-precision joints with reduced on-site drilling

Luminosa Structural Gutter: Perfect Complement to the Oval Tube

Key Luminosa Gutter Advantages

Structural Load Distribution

Reduced Shading and Thermal Bridges

Wide 9½-inch walking surface

- safer worker access during poly installation

- comfortable footing for maintenance

- faster and safer re-covers

Superior Water Managemen

- efficient rainfall evacuation

- optional condensation gutter separation

- improved interior climate control

Ideal Applications for Oval Tube Greenhouses

- commercial vegetable and fruit production

- high-tunnel berry systems

- multi-span gutter-connected greenhouses

- heavy-load crop systems (tomatoes, cucumbers, peppers)

- northern climates with snow load requirements

- TunnelPro Plus (freestanding tunnel system)

- Ovaltech (reinforced freestanding greenhouse)

- Luminosa (high-transmission gutter-connected structure)

The Oval Tube Greenhouse Is the Best Structural Choice

- Higher structural strength per pound of steel

- Wider arch spacing and more natural light

- Longer-lasting poly film

- Reduced installation and labour costs

- Safe drilling in the neutral axis

- Superior gutter integration in Luminosa models