Quality

Oval Tube

Structure

Design

Innovative plastic films

ROI

North-American greenhouse manufacturer since 1960

At Harnois, our oval tube greenhouse structure is engineered to deliver superior strength, light efficiency, and long-term performance in demanding commercial growing environments. Designed specifically for North American climate loads, this structural approach optimizes the strength-to-weight ratio of steel, reduces shading, and improves the durability of greenhouse coverings. The result is a high-performance oval tube greenhouse structure that supports stable climate control, higher yields, and a stronger return on investment throughout the greenhouse’s life.

Quality product

Structural Steel

Elastic limit: Minimum of 50,000 psi vs 33,000 psi Predicts steel's response to wind and snow constraintsGalvanization Type

Harnois Galvalume = 40+years Harnois Powercoat = 50+ years Standard G90 = 15 yearsHardware

The hardware is provided with a zinc-nickel coating, of industrial quality, ensuring a durable assembly quality and good corrosion protection with a minimum resistance under 1200 hours salt spray test according to ASTM B117, which is normally 500 hours according to the market standards.

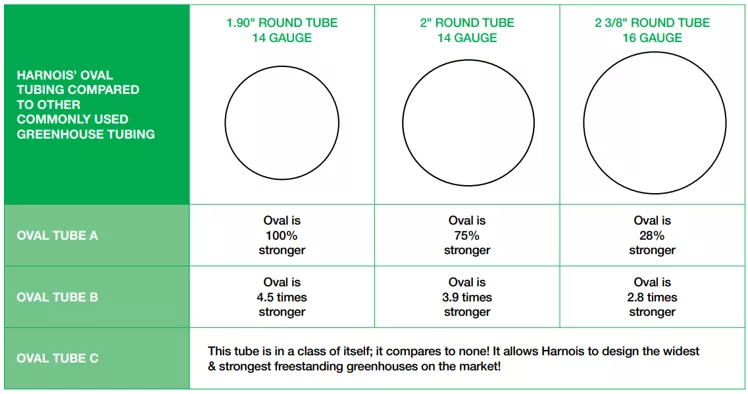

Oval Tube

optimized structure resistance

52% more resistant than other comparable profilesNo edges

It increases the poly film durability because there is no sharp edges and therefore, less frictionBest ratio

Our arches are made of oval tubing which offers the best ratio of strength to steel weight.Load Capacity

The oval tube has a superior load capacity for each arch, which allows greater arch spacing without compromising the oval tube greenhouse structure's integrity.

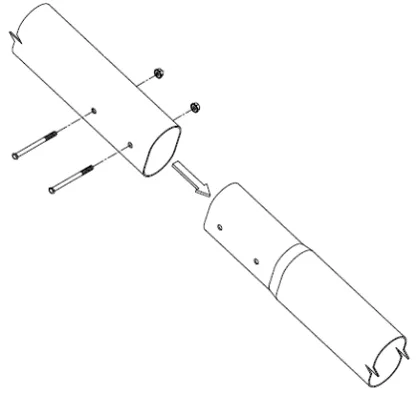

Structure

engineer stamp structure

For the Ovaltech and Luminosa

Drilling in the neutral axis

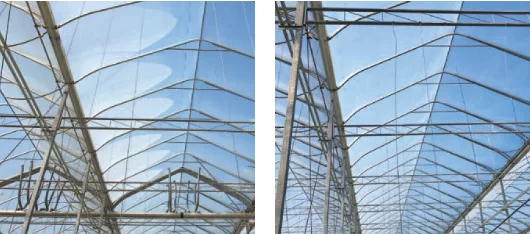

Drilling performed on the neutral axis preserves structural strength while minimizing on-site drilling and self-drilling screws through the use of bolted, swedged-tube assemblies.More Light Reaching the Crop

Thanks to the superior strength of Harnois steel structures, fewer structural elements are required in the roof. This reduces shading and allows more natural light to reach the plants, directly contributing to improved photosynthesis and higher yields.

Design

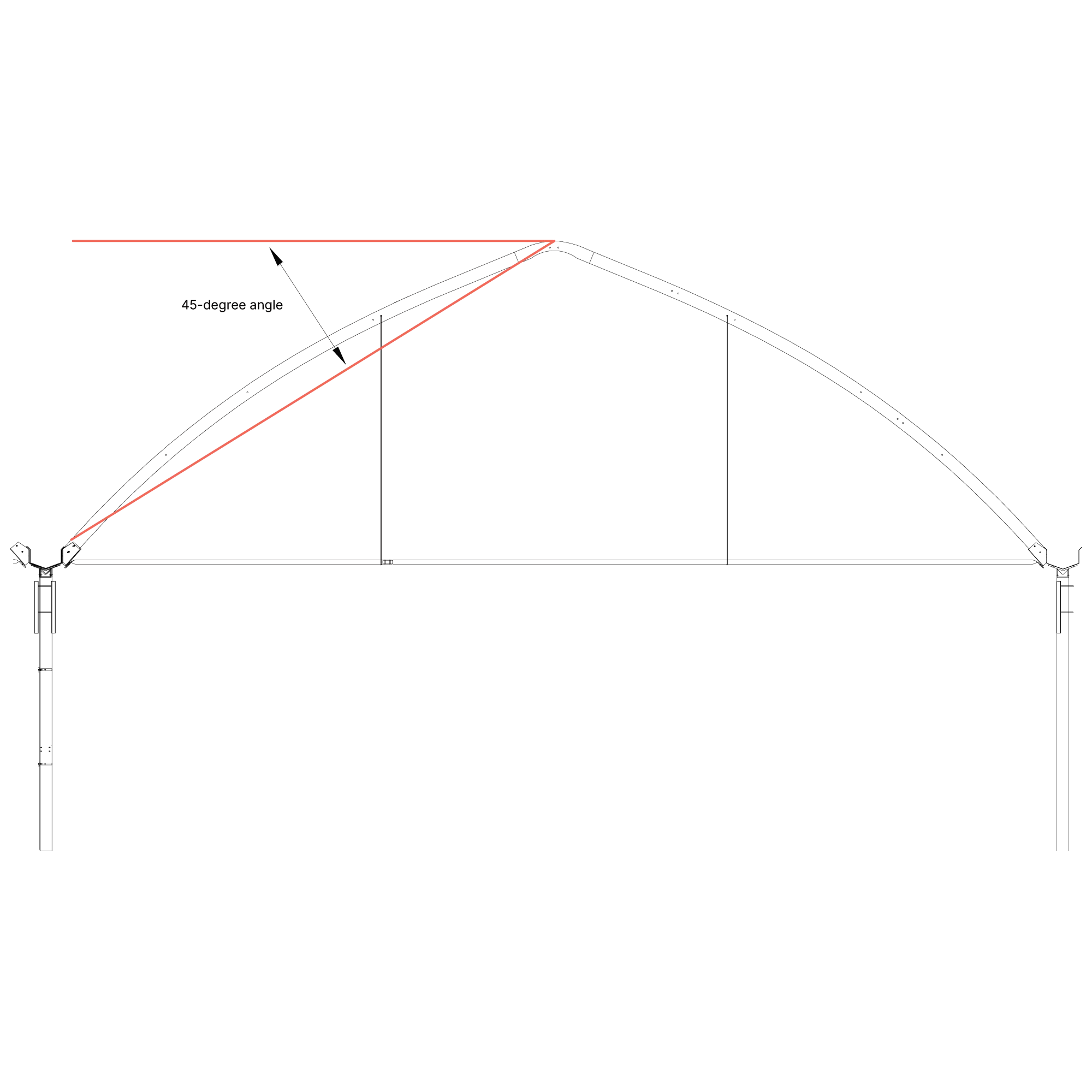

Optimal Roof Angle (45°)

The 45-degree gothic roof angle, combined with high-quality plastic films, optimizes light quality by filtering specific light wavelengths beneficial to plant development. This design also improves internal climate stability, helping growers maintain more consistent growing conditions.Higher Gable

A higher gable increases the volume available for hot air accumulation, improving climate conditions at plant level.Under-gutter (up to 20')

A higher under-gutter height (up to 20 ft) provides greater internal volume, enabling better climate control and improved energy efficiency.

Innovative greenhouse plastic films

8-layers

7 co-extruded layers + 8th layer on the surface of the filmAnti-Dripping

Non-migratory anti-dripping system that lasts much longer, thus offering a decisive advantage in humidity management and making it possible to use the film for more years.7,2mil thickness

Light transmission (90-91%)

Allow more light to enter the oval tube greenhouse structure. This becomes even more pronounced when ight incidence is low.No mist

Low temperature

It maintains its effectiveness at very low temperatures, even below −10 °C (14 °F), where traditional anti-drip films typically fail due to molecular crystallization.Optimal Roof Angle (45°)

The 45° roof slope creates optimal conditions for anti-drip performance, allowing our films to remain effective where traditional anti-dripping films require a minimum 30° inclination.Double-inflated

A crystal-clear outer film ensures maximum light transmission and mechanical resistance, while a thermic inner film minimizes heat loss.

Better ROI

Fast and simple installation

Reduced installation time and labor costs.Lower operational costs

Optimized ventilation and improved air volume reduce heating demand and energy expenses.Longer replacement cycles

High-strength plastic films and edge-free oval tubing reduce wear, extending covering lifespan.Reduced disease pressure

Improved climate control and condensation management protect crops.Stable growing conditions

More predictable production and planning.Higher yields and crop quality

Better light, climate, and structure performance drive results.Long-term durability (40+ years)

Extended lifespan reduces replacement and capital reinvestment.Low maintenance design

Fewer interventions, lower ongoing operating expenses.