Can You Grow Strawberries in a High Tunnel and What is the ROI?

Commercial high tunnel strawberry production offers significant advantages over open-field cultivation. High tunnels provide protection from extreme weather, extend the growing season, and improve fruit quality by reducing disease pressure. They create a controlled environment where temperature, humidity, and irrigation can be optimized, leading to higher yields and better berry consistency.

Where Is the Largest Producer of Strawberries?

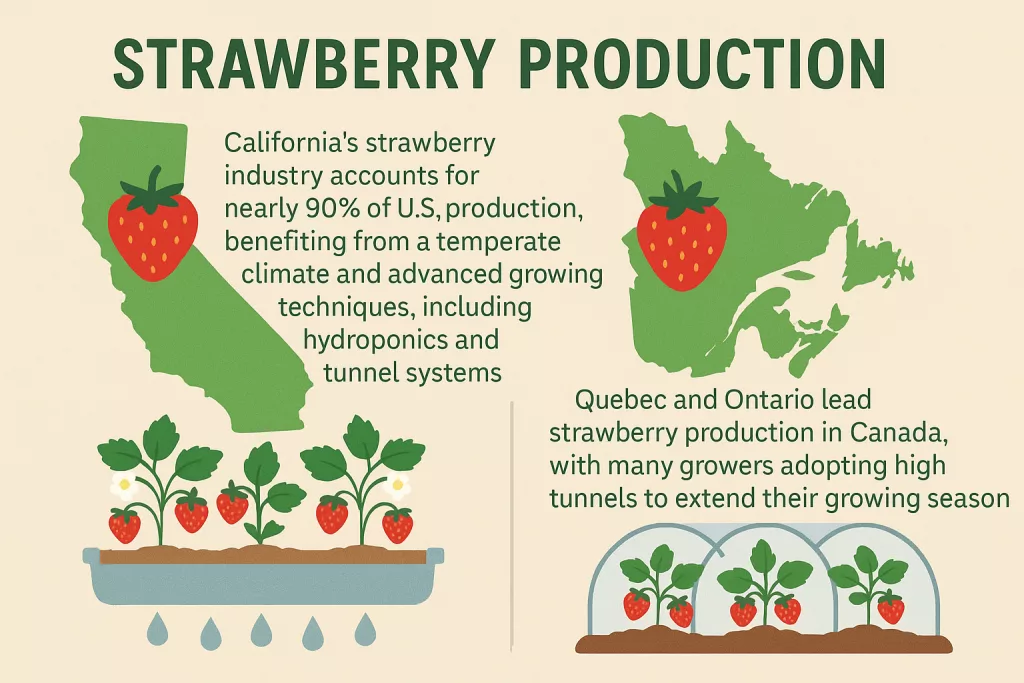

California’s strawberry industry accounts for nearly 90% of U.S. production, benefiting from a temperate climate and advanced growing techniques, including hydroponics and tunnel systems. Quebec and Ontario lead strawberry production in Canada, with many growers adopting high tunnels to extend their growing season.

Can You Grow Fruit Trees in a High Tunnel?

Yes, fruit trees can be grown in high tunnel greenhouses, though considerations like height, spacing, and pruning strategies must be carefully managed. Dwarf and semi-dwarf varieties of fruit trees, such as citrus, peaches, or figs, are the best candidates for commercial high tunnel strawberry production. These structures provide a frost-free environment that enhances early fruiting, protects against pests, and improves fruit quality. However, tree crops require a more permanent setup than strawberries and other small fruits.

Commercial high tunnel strawberry greenhouse: Yes, it's possible

Yes, high polytunnels, also called high tunnels, are widely used for commercial high tunnel strawberry production. Polytunnels offer a cost-effective way to protect strawberries from rain, frost, and extreme temperatures while enhancing fruit quality and yield. Growers using growing gutters in polytunnels can optimize production by improving air circulation, reducing disease risks, and facilitating labor efficiency during harvesting.

The Advantages of an growing gutters System for Strawberries

Using an growing gutters within a high tunnel provides multiple benefits:

- Better Disease Control: Keeping plants off the ground reduces soilborne diseases and pests exposure.

- Improved Harvesting Efficiency: Elevating plants to waist height makes harvesting faster and easier, reducing labor costs.

- Optimized Irrigation and Fertilization: Drip irrigation and fertigation systems can be precisely controlled, minimizing water waste and nutrient runoff.

- Higher Yields and Extended Harvest: Combining controlled climate conditions and optimized plant management leads to better fruit quality and increased production.

- Better Predictability to Meet Market Demand: A controlled environment ensures consistent production cycles, making it easier to meet delivery commitments for large-scale customers like grocery stores and distributors.

Commercial High Tunnel Strawberry Greemhouse: Dimensions

At 31.6 feet wide and 18 feet high, our high tunnels, TunnelPro Plus, are designed to provide ample space for growing gutters systems, ensuring optimal air circulation, temperature control, and efficient use of vertical space.

Commercial high tunnel strawberry production: Designed for Strawberries

- Increased Growing Capacity: The 31.6-foot width allows for multiple rows of growing gutters, maximizing space utilization.

- Improved Ventilation and Climate Control: With an 18-foot height, warm air rises away from the plants, reducing disease pressure and maintaining a stable growing environment.

- Ease of Access for Labor and Equipment: The high tunnel’s spacious design ensures workers can move efficiently between rows while facilitating mechanized tasks like irrigation and crop maintenance.

- Better Light Penetration: The wide structure helps evenly distribute natural light across all growing rows, boosting photosynthesis and improving fruit development.

- These dimensions enhance production efficiency, making our high tunnels ideal for commercial-scale strawberry farming with an growing gutters system.

Commercial high tunnel strawberry Production: Costs

For a one-acre (43,560 sq. ft.) setup, the estimated costs are (excluding installation):

Description | Cost per unit | Total cost |

|---|---|---|

Tunnel Structure & Covering | ~$2 per sq. ft. | $87,120 |

Growing Gutters & Irrigation System | ~$3 per sq. ft. | $130,680 |

Total | $217,800 per acre (excluding installation) |

Other costs include:

Description | Cost per unit | Total cost |

|---|---|---|

Strawberry Plants | $0.50 to $1 per plant | $7,500 to $20,000 |

Annual Labor & Maintenance | ~$0.50 per sq. ft. | $ 21,780 per year |

Fertilizer, Water, & Misc. Supplies | $5,000 to $10,000 per year | |

Total | $34,280 to $51,780 |

ROI Analysis for One-Acre of Commercial High Tunnel

Strawberry Production Strawberry Tunnel Production

Projected Revenue

- Yield Increase:

- Growing gutters can increase strawberry yields by 30–50%, reaching 35,000–50,000 lbs per acre annually.

- Selling Price:

- Fresh strawberries can sell for $3–$5 per pound in retail and direct markets.

- Annual Gross Revenue:

- $105,000 – $250,000 per acre

Payback Period

- First-Year Investment:

- $174,240 + $30,000 (plants, labor, and supplies) = ~$204,240

- Annual Profit (after costs):

- Conservative estimate:

- $105,000 revenue – ~$40,000 expenses = $65,000 profit

- Optimistic estimate:

- $250,000 revenue – ~$50,000 expenses = $200,000 profit

- Conservative estimate:

Commercial High Tunnel Strawberry Production: Long-Term Benefits

- Once the initial infrastructure is paid off, the profit margin increases, with annual earnings reaching $100,000+ per acre in an optimized system.

- Lower Risk: High tunnels protect against weather variability, reducing losses compared to open-field cultivation.

Commercial High Tunnel for Strawberry Greenhouse Production

Commercial High Tunnel Strawberry Production using an growing gutters offers a highly profitable, efficient, and predictable farming model. The controlled growing environment ensures consistent yields, premium fruit quality, and the ability to meet the strict demands of big retailers. While the initial investment may seem high, the fast ROI and long-term profitability make this system a smart choice for commercial strawberry greenhouse growers.