Investing in a commercial greenhouse is a strategic decision that directly impacts crop performance, operating costs, and long-term business stability. Professional growers are not simply purchasing a structure, they are selecting a production system that must perform reliably under real-world climate conditions, meet regulatory requirements, and adapt as operations scale. This commercial greenhouse buying commercial greenhouse buying guide is designed to help growers evaluate the most important factors before investing, from structural design and manufacturer selection to costs, automation readiness, permitting, and regional considerations across North America.

With decades of experience engineering greenhouse structures for demanding climates, Harnois approaches greenhouse design as a long-term partnership rather than a one-time transaction. The insights in this commercial greenhouse buying guide reflect proven design principles, real-world grower priorities, and the practical realities of operating commercial greenhouses in Canada, the United States, and Mexico; where durability, efficiency, and support matter as much as the structure itself.

Cost Transparency and Budget Planning

commercial greenhouse buying guide

Choosing the Right Greenhouse Manufacturer

commercial greenhouse buying guide

commercial greenhouse buying guide

Navigating Permits and Regulations

Canada

United States

Mexico

Regional realities

commercial greenhouse buying guide

Integrating Technology and Automation

Building A Greenhouse? Don't Make These Mistakes!

In this week’s episode, JM Fortier reviews the installation process of his new Harnois greenhouse and shares 5 tips that he learned over the years to help you install a greenhouse on your farm. The installation of a greenhouse is an important project for the profitability of a farm. However, the learning curve for selecting the right infrastructure and equipment can be steep, and adapting to growing crops in a controlled environment can be a challenge.

Check out our course Mastering Greenhouse Production so you can avoid a lot of costly mistakes and run a successful greenhouse operation.

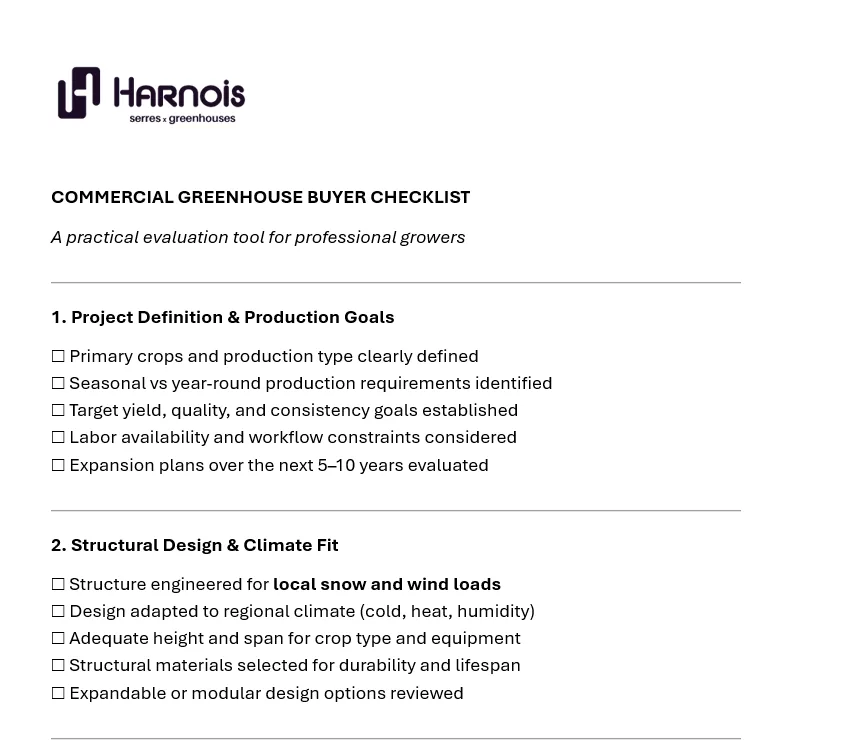

COMMERCIAL GREENHOUSE BUYER CHECKLIST

Selecting a commercial greenhouse is a long-term investment that affects production efficiency, operating costs, regulatory compliance, and business growth. Too often, decisions are made based on upfront price or surface-level specifications, without fully evaluating how a structure will perform over its entire lifespan or how well a manufacturer supports the project from design through operation.

This checklist is designed to help professional growers take a structured, objective approach when evaluating greenhouse projects and manufacturers. It highlights the key technical, operational, and strategic considerations that should be reviewed before committing to a purchase, including structural design, climate adaptation, automation readiness, permitting requirements, and long-term support.

Use this checklist, part of the commercial greenhouse buying guide, as a practical tool to compare options, guide discussions with manufacturers, and ensure that the greenhouse you choose is engineered not only to meet today’s needs, but to support future expansion, efficiency, and reliability.